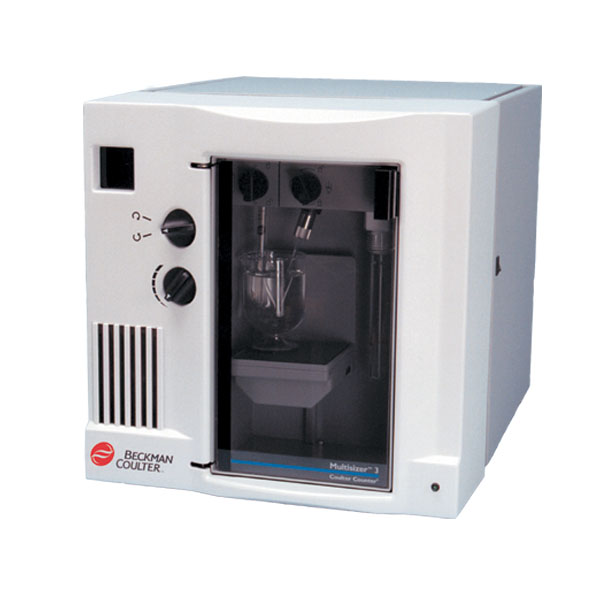

Beckman Coulter

- Multisizer™ 3 COULTER COUNTER®

- More than half a century of experience counting and sizing particles and cells

- Used in approved ASTM methods

- Technology defined by the International Standard ISO 13319 (ISO 13319:2000: Determination of particle size distributions -- Electrical sensing zone method)

- Accurate sizing, counting and high resolution technology preferred by the industry for particle counting and size distribution

- Capable of counting and sizing particles at concentration levels not detected by other technologies

- Color or refractive index does not affect results

- Easy to operate: Instrument completely controlled through the computer with user-friendly software

- Digital Pulse Processor: Real-time measurements- Detection of any change in the sample over the length of the analysis. The pulse distribution offers information about the sample behavior such as cell volume, dissolution, agglomeration, etc.

- Suitable for both aqueous and organic electrolytes

- Environmentally friendly, mercury-free metering system

- New aperture system (no grease) makes it easy to reconfigure for a desired size range

- Resolution can be selected from 4 to 300 channels at any selected range

- User defined Standard Operation Procedures (SOPs)

- Multiple security levels

- Enables 21 CFR part 11 Compliance

- Powerful and flexible software allows the processing and presentation of data to fit all needs

- Trending capability allows for easy and quick monitoring of any process

- Certification Program to ensure instrument performance

- V-Check (IQ, OQ, PQ) instrument validation

- Cell Growth

- Cell Cycle

- Cell Death

- Compensation for Osmotic Stress

- Pathogenesis

- Phagocytosis

- Proven technology

- Superior instrument design

- Quality assurance friendly

- Digital Pulse Processor (DPP)

- Easy to operate, user-friendly software

- Resolution can be selected from 4 to 300 channels at any selected range

- V-Check (IQ, OQ, PQ) instrument validation

Power Consumption: Less than 250 W

up to 300 for any selected range

Dynamic Range of Aperture: 30:1 by diameter, 27,000:1 by volume

Interface: TCP/IP to IBM compatible PC, running Win95, 98, 2000, NT 4.0

Linearity: Linear response ±1% of pulse height over selected range

Overall Analysis Range: 0.4 µm to 1200 µm diameter 0.036 to 904.8 x 106 fL or µm³ volume

Power Requirements: 100 - 120 V AC ± 10% 50/60 Hz

220 - 240V AC ± 10% 50/60 Hz

Resolution: User Selectable

Dimensions and Weight (excluding computer): Height: 45 cm (17.75 in)

Width: 43 cm (17 in)

Depth: 63.5 cm (25 in)

Weight: 34 kg (75 lb)

The Multisizer 3 provides highly accurate particle counting and sizing information utilizing the Coulter Principle

Proven Coulter Technology Ensures Your Results are Accurate & Reliable

Improved Instrument Design

Automated Quality Assurance Functions Put You in Control of the Results

Overlay & Size Trend -- MCV (Mean Cell Volume) Changes

Change in cell volume is an important factor involved in many biological processes.

The Multisizer 3 is capable of detecting cell size and volume changes even if they happen over a few seconds or in a period of several hours. Using the Overlay function allows for visualization and comparison of cell populations with different sizes.

High Sensitivity -- Solid Contaminants in Liquids

The determination of particle size and number is used to establish the level of insoluble material contaminating liquids. Usually the concentration of non-soluble contaminants is too low to be characterized with any other technology, but with the Multisizer 3 purification processes can easily be monitored.

Multi-Tube Overlap -- Determining Bacterial Aggregation in a Culture

Bacterial aggregates can reduce the effectiveness of antimicrobial agents. A combination of detergents and filters can be used to decrease the amount of 'clumps'. The percentage of 'clumps' relative to single cells can be determined by using two different apertures. The Multi-Tube Overlap function merges the results into a single continuous distribution.

Size Interpolation -- ISO Solid Contaminant Code for Hydraulic Fluids and Lubricants

The Multisizer 3 software can be used to create sample data reports that will arrange the data to conform to a set of user defined boundaries, also called “channels”, “bins”, or “size classes” (this is similar to how particle data points are reported when different size sieves are used). The ISO Solid Contaminant Code for Hydraulic Fluids and Lubricants is based on the number of particles larger than a series of given sizes. The Size Interpolation function allows the arrangements of the data to classify oils and lubricants as defined by this international standard.

Standard Operating Procedures -- Consistency and Uniformity for Analysis and Results

The easy creation of SOP’s allows the standardization of analysis methods and the reporting of results. The use of SOP’s guarantee consistency and uniformity regardless of the number of applications, operators, instruments and locations involved.

Particle Count / Size Distribution -- Control of Particle Size of Raw Material

Traditionally volume % size distribution is used to characterize powders because the results are comparable to sieve results, an old technology used for many years. If the size distribution is not Gaussian, the fine particles of the main population are not shown when using volume %. If the presence of fine particles could affect the quality of a product or process, the Multisizer provides both, volume % and number % size distributions.

Digital Pulse Processing (DPP) -- Real-Time Size Change Detection

The use of a Digital Pulse Processor (DPP) allows the detection of changes in cells or particles in real time, even if it takes place over a few seconds. Using pulse data it is also possible to study the rate of dissolution for a population of particles. The change in the pulses generated during an analysis where particles are dissolving shows how the mean size of the population changes as the dissolution process advances. The use of a Digital Pulse Processor (DPP) also allows storing all the original information from the pulses generated at the moment of the analysis. High-speed digitization of the signal allows the use of pulse area analysis and other techniques for additional particle characterization. This information may be used at a later time to recalculate the size distribution for a different range, number of channels, or even to change the calibration constant, thus eliminating the need for re-analysis of the sample. In addition to the size distribution, the DPP data also calculates the pulse distribution. By looking at the pulse distribution graph, it is possible to know if the sample preparation was stable over the length of the analysis. An unevenly distributed pulse pattern is an indication of changes in the dispersed sample that otherwise would not be possible to detect with the size distribution graph.

Powerful and Flexible Software

The user-friendly and flexible software that is packaged with the Multisizer™ 3 provides the operator with a vast array of information at the click of a mouse. The software allows the customization of SOPs, SOM and printed reports. Whether for Biological, Industrial, Quality Control and/or Research applications, the Multisizer™ 3 software will satisfy any requirements for the presentation of results.

Regulatory Compliance 21 CFR Part 11

The Electronic Records and Electronic Signatures Rule (21 CFR Part 11) was established by the FDA to define the requirements for submitting documentation in electronic form and the criteria for approved electronic signatures. This rule, which has been in effect since August 20, 1997, does not stand in isolation; it defines the standards by which an organization can use electronic records to meet its record-keeping requirements. Organizations that choose to use electronic records must comply with 21 CFR Part 11. It is intended to improve an organization’s quality control while preserving the FDA's charter to protect the public. Since analytical instrument systems such as the Multisizer™ 3 generate electronic records, these systems must comply with the Electronic Records Rule. By selecting the 21 CFR Part 11 option in the software, the system automatically reconfigures to comply with these regulations. In addition to 21 CFR Part 11, the software offers other security levels that may be customized by the user.

V-Check Program

Beckman Coulter Inc. is regulated by the United States Food and Drug Administration (FDA) for compliance with current Good Manufacturing Practices (cGMP's) for medical devices. This gives Beckman Coulter a unique understanding of the strict requirements that users in regulated industries are subjected to. As a result, Beckman Coulter has established a comprehensive program to address all aspects of the instrument validation. The V-Check program is a comprehensive package that addresses all appropriate aspects of a product’s life cycle, from instrument development to ongoing performance verification (SQ, DQ, IQ, OQ and PQ). The V-Check program contains all the necessary documentation for instrument validation. This documentation is required to show auditors and investigators proof of proper instrument validation. It consists of a number of functional inter-linked components, which have been designed to give the user assurance that the product is fit for the purpose that it has been designed for and will perform on a consistent basis for these tasks. Where other instrument manufacturers leave off, Beckman Coulter and its V-Check program assist with ongoing quality checks of the instrument (PQ). This proves that it is important to consider products from a manufacturer who not only understands your needs, but is also willing to develop a partnership for the future.

Features